Table of Contents

Top 10 Essential Crane Parts Every Operator Should Know

Cranes are essential pieces of equipment in various industries, from construction to manufacturing. They are used to lift and move heavy loads with precision and efficiency. To ensure the safe and effective operation of a crane, it is important for operators to have a good understanding of the different crane parts and their functions.

One of the top crane parts that every operator should know is the boom. The boom is the long, horizontal arm of the crane that is used to lift and move loads. It can be extended or retracted to reach different heights and distances. The boom is typically made of steel or aluminum and is supported by a series of cables and pulleys.

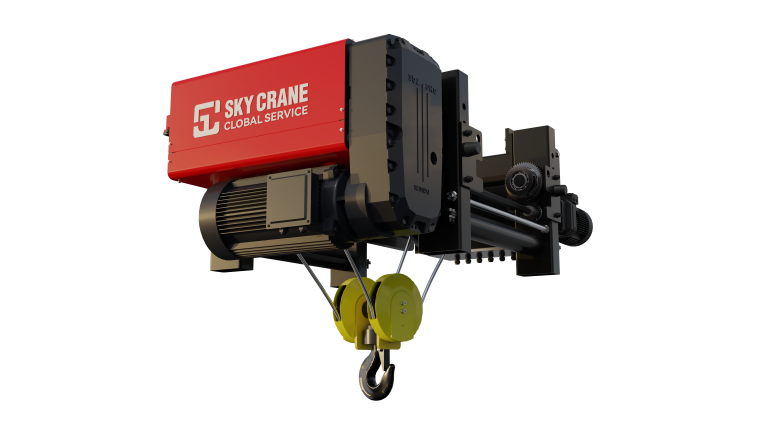

Another important crane part is the hoist. The hoist is the mechanism that is used to lift and lower loads. It consists of a motor, a drum, and a set of cables or chains. The hoist is controlled by the operator using a control panel or remote control. It is important for operators to understand how to properly operate the hoist to ensure the safe lifting and lowering of loads.

The jib is another essential crane part that operators should be familiar with. The jib is a horizontal arm that is attached to the top of the crane’s boom. It is used to provide additional reach and flexibility when lifting loads. The jib can be fixed or adjustable, depending on the type of crane. Operators should know how to properly position and secure the jib to ensure safe operation.

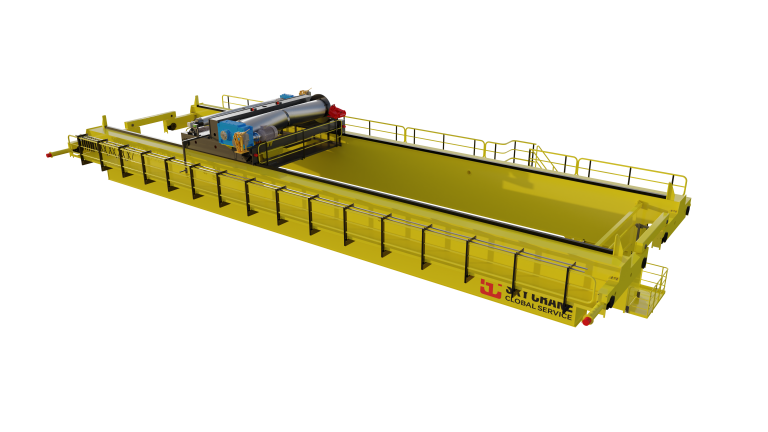

The counterweight is another important crane part that helps to balance the crane and prevent it from tipping over. The counterweight is typically located at the rear of the crane and is made of concrete or steel. It is important for operators to understand how to properly position and adjust the counterweight to ensure the stability of the crane during lifting operations.

The outriggers are another essential crane part that operators should be familiar with. The outriggers are extendable legs that are used to provide additional stability to the crane. They are typically deployed when lifting heavy loads or working on uneven terrain. Operators should know how to properly extend and retract the outriggers to ensure the safe operation of the crane.

The slew ring is another important crane part that allows the crane to rotate 360 degrees. It is located at the base of the crane and is connected to the boom. The slew ring is controlled by the operator using a control panel or joystick. Operators should know how to properly rotate the crane using the slew ring to position the load accurately.

The hook block is another essential crane part that is used to attach the load to the crane. It consists of a hook and a block with multiple sheaves. The hook block is attached to the hoist and is used to lift and lower loads. Operators should know how to properly attach and secure the load to the hook block to ensure safe lifting operations.

The load moment indicator (LMI) is another important crane part that helps operators to monitor the load capacity of the crane. The LMI displays information such as the weight of the load, the radius of the boom, and the angle of the boom. It provides visual and audible warnings if the crane is being operated beyond its capacity. Operators should know how to read and interpret the information displayed on the LMI to ensure safe lifting operations.

The boom angle indicator is another essential crane part that helps operators to position the boom at the correct angle. It displays the angle of the boom relative to the ground and helps operators to determine the maximum safe working radius. Operators should know how to read and interpret the information displayed on the boom angle indicator to ensure safe lifting operations.

In conclusion, understanding the different crane parts and their functions is essential for operators to ensure the safe and effective operation of a crane. By knowing how to properly operate and maintain these essential crane parts, operators can help to prevent accidents and ensure the efficient lifting and moving of heavy loads.

A Comprehensive Guide to Choosing the Best Chinese Crane Parts Manufacturer

When it comes to choosing a Chinese crane parts manufacturer, there are several factors to consider in order to ensure that you are getting the best quality products for your needs. With the growing demand for cranes in various industries, it is important to find a reliable and reputable manufacturer that can provide you with the necessary parts to keep your equipment running smoothly.

One of the most important factors to consider when choosing a Chinese crane parts manufacturer is the quality of their products. It is essential to ensure that the manufacturer uses high-quality materials and follows strict quality control measures to produce durable and reliable crane parts. Look for manufacturers that have a good reputation for producing top-notch products that meet industry standards.

| No. | Commodity Name |

| 1 | LDP electric single beam |

| 2 | Double – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In addition to quality, it is also important to consider the range of products offered by the manufacturer. A reputable Chinese crane parts manufacturer should offer a wide variety of parts for different types of cranes, including overhead cranes, gantry cranes, and jib cranes. This will ensure that you can easily find the parts you need for your specific equipment without having to search elsewhere.

Another important factor to consider is the manufacturer’s experience and expertise in the industry. Look for manufacturers that have been in business for many years and have a proven track record of providing high-quality crane parts to customers. Experienced manufacturers are more likely to have the knowledge and skills necessary to produce top-notch products that meet your specific requirements.

When choosing a Chinese crane parts manufacturer, it is also important to consider their customer service and support. A reputable manufacturer should have a dedicated customer service team that is available to assist you with any questions or concerns you may have. Look for manufacturers that offer prompt and efficient customer support to ensure that you have a positive experience when purchasing crane parts.

Price is another important factor to consider when choosing a Chinese crane parts manufacturer. While it is important to find a manufacturer that offers competitive prices, it is also important to remember that quality should not be compromised for the sake of saving money. Look for manufacturers that offer a good balance between quality and affordability to ensure that you are getting the best value for your money.

In conclusion, choosing the best Chinese crane parts manufacturer requires careful consideration of several factors, including quality, range of products, experience, customer service, and price. By taking the time to research and compare different manufacturers, you can find a reliable and reputable supplier that can provide you with high-quality crane parts for your equipment. Remember to prioritize quality and reliability when making your decision to ensure that your cranes continue to operate efficiently and safely.